A vibratory tumbler is a piece of equipment used in the process of vibratory finishing. Vibratory finishing is one of the most used procedures when performing mass finishing. Read More…

Otec USA Inc. is a world-class supplier of mass finishing equipment and supplies. Our primary products include centrifugal disc, drag and stream finishing machines to meet all of your deburring, polishing, grinding and honing requirements.

Giant Finishing is a well-known manufacturer of deburring equipment and machinery, media and compounds, molding vibratory bowls, multi-stage washers and more. We have over 100 standard models to choose from, or we can custom-manufacture products to meet your needs! In business for two decades, we provide the mass-finishing industry with complete equipment solutions.

Great Lakes Finishing Equipment, Inc. is a leading supplier of the deburring equipment, machines, and supplies for all your mass finishing projects. This equipment includes continuous systems, vibratory bowls, tubs, and high energy centrifugal barrel machines. Let our deburring specialists work with you to find the best deburring machinery for your project.

At ESMA, Inc., we specialize in designing and manufacturing advanced deburring equipment that streamlines precision finishing across a wide range of industries. With decades of experience at the forefront of electropolishing and metal finishing technologies, we’ve developed solutions that eliminate manual labor, reduce cycle times, and deliver consistent, high-quality results.

More Vibratory Tumbler Manufacturers

Vibratory Tumblers: The Ultimate Guide to Industrial Surface Finishing

Vibratory tumblers are essential equipment in the world of industrial finishing, providing efficient, automated solutions for deburring, polishing, surface smoothing, and cleaning a wide variety of workpieces. Whether in aerospace, automotive, medical device manufacturing, or jewelry production, vibratory tumblers play a crucial role in achieving precise, uniform finishes and reducing manual labor costs. This comprehensive guide covers how vibratory tumblers work, their types, primary applications, operational benefits, and key factors to consider when selecting the best vibratory tumbler supplier for your unique production needs.

How Vibratory Tumblers Work: The Industrial Finishing Process Explained

Vibratory tumblers utilize a process called vibratory finishing, a cornerstone of mass finishing technology. To begin, unfinished parts and workpieces are placed into a tub or bowl filled with specially shaped abrasive or polishing media pellets. The machine's motor generates controlled vibrational forces, causing both the parts and media to move against each other in a consistent, rolling action. A finishing compound or chemical additive may be introduced to enhance cleaning, degreasing, or polishing results.

This vibrational energy gently grinds, polishes, or deburrs the surfaces of each component, delivering a uniform finish while minimizing the risk of part-on-part damage. The result is a batch of neatly polished, deburred, or cleaned workpieces ready for subsequent manufacturing steps, coating, or assembly.

Key Steps in Vibratory Finishing:

- Loading workpieces and media into the tumbler tub or bowl

- Adding appropriate finishing compounds (degreasers, polishers, or abrasives)

- Initiating vibratory action to facilitate media and part interaction

- Continuous monitoring of process time and desired surface finish

- Unloading and separating finished parts from the media

Are you looking for tips on optimizing your vibratory finishing process? Scroll down to our Applications and Uses section or jump to Choosing a Supplier to find answers to commonly asked questions about vibratory tumbling, media selection, and finishing best practices.

Types of Vibratory Tumblers: Choosing the Right Machine for Your Application

There are several types of vibratory tumblers, each engineered for specific production requirements and workpiece geometries. Understanding the differences will help you select the optimal machine for your finishing needs.

Vibratory Bowl Finishing Machines

The vibratory bowl finisher—sometimes called a vibratory bowl tumbler—is designed with a circular tub lined with durable polyurethane. Among all vibratory finishing equipment, the bowl configuration is the simplest and most widely used. The polyurethane lining minimizes the friction coefficient between the abrasive media and the bowl wall, protecting both from excessive wear and ensuring long machine life.

Adjustable dividers within the bowl allow for customized processing of unique or delicate parts, reducing part-to-part contact and damage. Vibratory bowl finishers support both large and small batch processing, making them versatile for a range of industries including automotive, aerospace, and precision engineering.

Vibratory Trough (Tub) Finishing Machines

Vibratory trough finishers, also known as vibratory tub finishers, are ideal for handling irregular, long, large, or fragile workpieces that cannot be processed effectively in standard bowls. These machines feature a U-shaped tub, often segmented by divider plates, all lined with abrasion-resistant polyurethane to protect both parts and machinery.

The ability to create separate sections within the tub reduces friction and prevents parts from impacting each other. This makes trough finishers the preferred choice for finishing large, delicate, or oddly shaped components, such as turbine blades, shafts, extrusions, and castings. Available in various sizes and capacities, they accommodate high-volume production runs as well as custom, small-batch requirements.

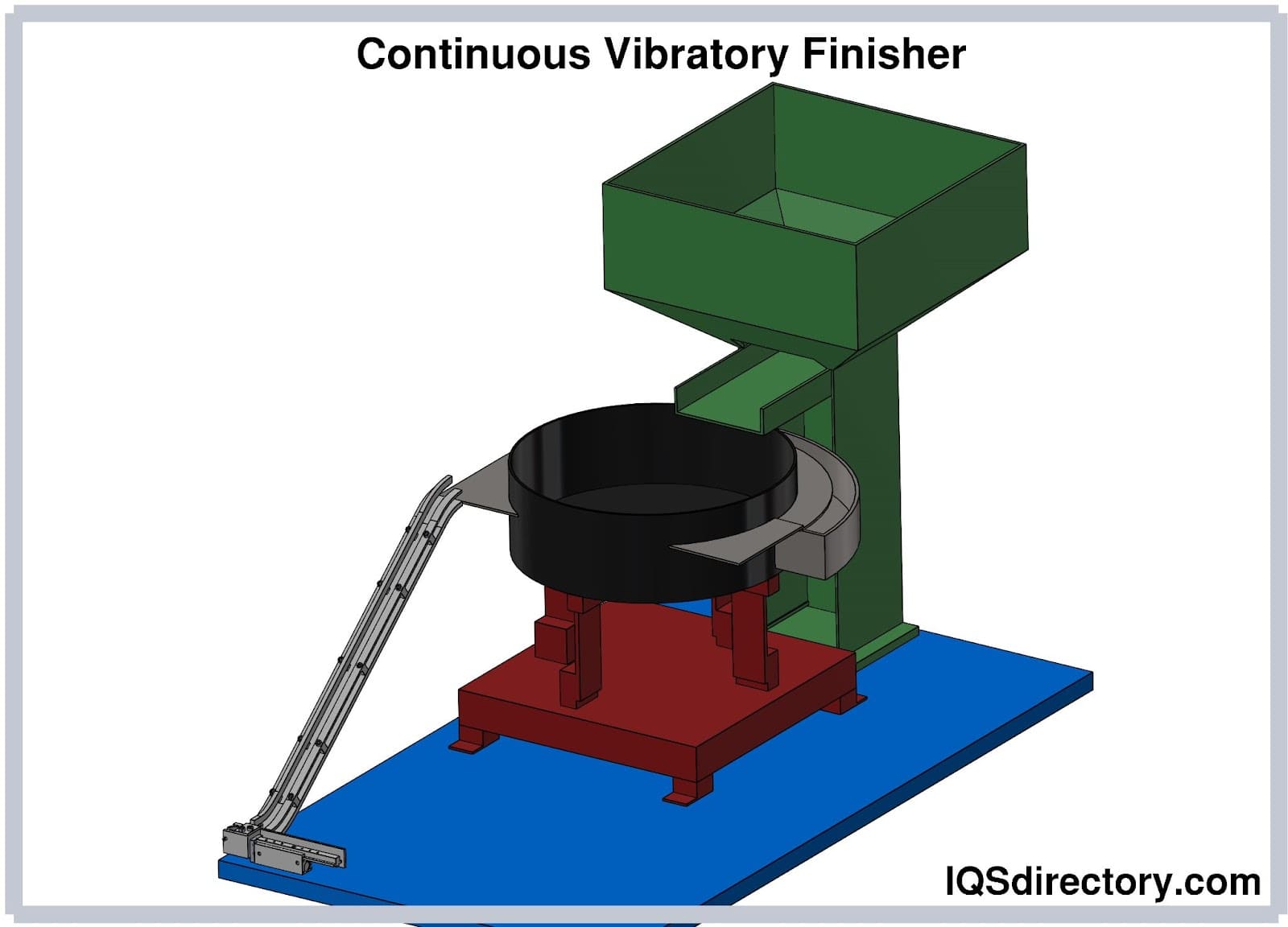

Continuous Vibratory Finishers

A continuous vibratory finisher is engineered for non-stop, in-line production environments. In these systems, unfinished parts are continuously fed into one end of the machine, where they are mixed with abrasive media and compounds. While the vibratory motion is ongoing, the parts traverse the length of the tub and emerge at the opposite end, fully finished and ready for the next process.

Continuous systems maximize productivity and are ideal for manufacturers with high-throughput requirements and automated workflows. They are often integrated into larger production lines in sectors such as automotive, metal fabrication, hardware production, and consumer goods.

Vibratory Dual Finishing Machines

Dual finishing machines feature both an inner and an outer chamber, enabling the simultaneous performance of wet and dry finishing steps. The inner chamber typically carries out heavy-duty operations such as aggressive deburring, edge radiusing, or high-gloss polishing, while the polyurethane lining protects against premature wear.

The outer chamber is dedicated to cleaning or drying the parts post-processing, separated by a partition to prevent cross-contamination. Dual finishing machines are especially useful in applications where both dry and wet finishing are required in a single workflow, increasing efficiency and reducing handling time.

Vibratory Dryers

After wet finishing processes, efficient drying is critical to prevent corrosion, staining, or spotting on metal parts. Vibratory dryers are equipped with heated drying media in specially designed tubs and are available in both batch and continuous modes. They are capable of handling both small and large production volumes, ensuring that parts are dried thoroughly and quickly before further assembly or packaging.

Want to compare vibratory tumblers for your specific part geometry or production needs? Check out our supplier selection tips or explore application scenarios below.

Applications and Uses of Vibratory Tumblers: From Precision Deburring to Surface Preparation

Vibratory tumblers are used across a wide spectrum of industries for diverse finishing tasks. Their versatility, scalability, and ability to automate surface finishing make them indispensable for modern manufacturing.

Common Applications of Vibratory Tumblers

- Deburring: Removing sharp edges, burrs, and residual material from machined, stamped, or cast parts for improved safety and fit.

- Descaling: Eliminating oxidation, scale, or rust from metal surfaces prior to painting, plating, or further processing.

- Deflashing: Smoothing away excess flash or mold lines from plastic or die-cast components.

- Polishing: Achieving a uniform, high-gloss, or matte finish on metal, plastic, or ceramic workpieces.

- Surface Preparation: Conditioning surfaces for optimal adhesion of coatings, paints, or electroplating.

- Rounding or Edge Radiusing: Creating consistent edge profiles to reduce wear or facilitate assembly.

- Cleaning: Removing oils, coolants, and other contaminants as part of pre-assembly or post-machining cleaning routines.

- Size Reduction or Shaping: Refining irregularly shaped materials to precise dimensions and geometries.

Industries That Rely on Vibratory Tumblers

- Automotive: For mass deburring and polishing of engine parts, fasteners, brackets, and transmission components.

- Aerospace: Ensuring tight tolerances and smooth finishes on critical turbine blades, airframe components, and fasteners.

- Medical Device Manufacturing: Achieving biocompatible, burr-free surfaces on implants, surgical tools, and dental instruments.

- Jewelry and Watchmaking: Polishing and burnishing precious metals and gemstones for high-luster finishes.

- Firearms and Defense: Smoothing and finishing barrels, receivers, and other precision components.

- Electronics: Cleaning and preparing connector pins, housings, and enclosures for assembly or plating.

- General Metalworking and Fabrication: Large-scale deburring, cleaning, and finishing of sheet metal, castings, and machined parts.

Curious about the best vibratory tumbler for your application? Ask these key questions when choosing a supplier or learn more about selecting the right tumbling media for your parts.

Benefits of Vibratory Tumblers: Why Choose Vibratory Over Rotary or Manual Finishing?

- Efficiency and Throughput: Vibratory tumblers process large volumes of parts simultaneously, significantly reducing manual labor and turnaround time compared to hand finishing or rotary tumblers.

- Consistent Results: The uniform movement of media and parts ensures highly consistent finishes across all workpieces, critical for quality control and repeatability.

- Versatility: Suitable for a vast range of part shapes, sizes, and materials—from tiny fasteners to long extrusions and delicate components.

- Gentle Action: The controlled vibrational process minimizes part damage and preserves fine details, making vibratory finishing ideal for precision components.

- Customizability: Wide variety of media types (ceramic, plastic, steel, organic) and finishing compounds available to tailor surface roughness, gloss, or cleanliness to exact specifications.

- Cost Savings: Reduced manual intervention, lower per-part finishing costs, and minimized rework or scrap due to surface defects.

- Scalability: Machines available for everything from prototype batches to high-volume, fully automated production lines.

- Environmental Benefits: Modern vibratory tumblers often feature closed-loop process water recycling, reducing chemical and water usage.

Trying to decide between a vibratory tumbler and other mass finishing equipment? Explore factors to consider or discover what media is best for your application.

Factors to Consider When Selecting a Vibratory Tumbler

- Workpiece Size and Geometry: Choose a machine type and size that accommodates your largest, most complex parts without causing part-on-part damage.

- Production Volume: Assess whether batch, continuous, or dual-action machines best fit your throughput requirements.

- Desired Surface Finish: Match media type, compound, and cycle time to your required roughness, gloss, or cleanliness specifications.

- Automation Level: For lean manufacturing or Industry 4.0 environments, consider integration with conveyors, loaders, or process monitoring systems.

- Media Selection: Different abrasives (ceramic, plastic, steel, organic) deliver varied cutting actions and finishes. Test with sample parts when possible.

- Ease of Maintenance: Polyurethane linings, robust drives, and accessible controls ensure long-term reliability and lower downtime.

- Safety and Compliance: Confirm that machines meet all applicable workplace safety and environmental regulations.

Choosing the Right Vibratory Tumbling Media and Compounds

The choice of tumbling media is a critical factor in achieving optimal results with your vibratory tumbler. Media acts as the abrasive agent in the finishing process, influencing the rate of material removal, surface smoothness, and final appearance of your workpieces.

- Ceramic Media: Delivers aggressive cutting action, ideal for heavy deburring and rapid material removal on hard metals.

- Plastic Media: Provides gentler action, suited for aluminum, brass, softer alloys, or delicate parts where surface preservation is critical.

- Steel Media: Used for burnishing and achieving high-gloss finishes on steel, stainless, or non-ferrous metals.

- Organic Media (Corn Cob, Walnut Shell): Preferred for drying, cleaning, or light polishing without abrasion.

- Specialty Media: Includes porcelain, glass beads, or custom shapes for niche applications.

Finishing compounds enhance cleaning, degreasing, corrosion inhibition, or brightness. Testing with actual parts and media samples is recommended to dial in the best combination for your production goals.

Choosing the Proper Vibratory Tumbler Supplier: A Step-by-Step Guide

To ensure you achieve the best results and ROI when purchasing vibratory tumblers or vibratory finishing equipment, it is vital to carefully evaluate potential suppliers. Here’s how to make an informed decision:

- Compare at least 4 companies using our comprehensive Vibratory Tumbler Directory to view available models, industry expertise, and support services.

- Review each supplier’s business profile for their finishing experience, manufacturing capabilities, and after-sales support.

- Use the integrated contact form to request technical specs, sample processing, or a custom quote directly from the manufacturer.

- Preview supplier websites using our patented previewer to quickly assess their specialties and product range.

- Leverage the simple RFQ form to contact multiple suppliers at once—compare quotes, lead times, and value-added options.

Questions to ask when evaluating vibratory tumbler suppliers:

- What industries and part types does the supplier specialize in?

- Can they provide sample processing or test runs to validate results?

- Do they offer technical support, spare parts, and maintenance services?

- Are custom machine designs or automation options available?

- What is the warranty and after-sales service coverage?

- How do they support process optimization or media selection?

For more tips on evaluating industrial finishing equipment suppliers, visit our Vibratory Finishing Resource Center or reach out for customized recommendations.

Frequently Asked Questions About Vibratory Tumblers

- What is the difference between vibratory and rotary tumblers?

Vibratory tumblers use high-frequency vibration to cause media and parts to rub against each other, resulting in faster, more uniform finishes. Rotary tumblers tumble parts and media together in a spinning barrel, which can be slower and less controlled, especially for delicate or irregular parts. - How do I choose the right size and type of tumbler?

Consider your largest part dimensions, daily production volume, and required surface finish. Bowl machines are ideal for general batch processing; trough/tub machines are best for long or fragile parts; continuous machines suit high-volume, automated lines. - Which media is best for deburring aluminum?

Plastic media is often preferred for deburring aluminum due to its gentle action and ability to preserve surface details. Ceramic media may be used for more aggressive cutting when needed. - Can vibratory tumblers be used for parts cleaning only?

Yes, with the right combination of cleaning compounds and media, vibratory tumblers excel at degreasing, descaling, and cleaning parts prior to assembly or finishing. - Is it possible to automate the vibratory finishing process?

Absolutely. Many modern vibratory tumblers offer automated loading, unloading, process monitoring, and integration with other finishing or inspection equipment.

Get Started: Request Quotes or Expert Advice

Ready to take your surface finishing to the next level? Request a quote from leading vibratory tumbler manufacturers, or explore our knowledge base for detailed guides on process optimization, media selection, and troubleshooting. Whether you’re upgrading existing equipment, launching a new product line, or seeking to improve finishing quality, our experts are here to help you achieve the best results.

Still have questions about vibratory tumblers, media, or finishing processes? Contact our team for personalized advice or to arrange a sample processing trial.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services