Tumbling media refers to preformed, abrasive material that is used for polishing and finishing parts made up of various materials. By scrubbing parts against abrasive materials, those surfaces are thoroughly abraded and smoothed. The process also helps in removing rough metal ridges called burrs. Read More…

Otec USA Inc. is a world-class supplier of mass finishing equipment and supplies. Our primary products include centrifugal disc, drag and stream finishing machines to meet all of your deburring, polishing, grinding and honing requirements.

Giant Finishing is a well-known manufacturer of deburring equipment and machinery, media and compounds, molding vibratory bowls, multi-stage washers and more. We have over 100 standard models to choose from, or we can custom-manufacture products to meet your needs! In business for two decades, we provide the mass-finishing industry with complete equipment solutions.

Great Lakes Finishing Equipment, Inc. is a leading supplier of the deburring equipment, machines, and supplies for all your mass finishing projects. This equipment includes continuous systems, vibratory bowls, tubs, and high energy centrifugal barrel machines. Let our deburring specialists work with you to find the best deburring machinery for your project.

At ESMA, Inc., we specialize in designing and manufacturing advanced deburring equipment that streamlines precision finishing across a wide range of industries. With decades of experience at the forefront of electropolishing and metal finishing technologies, we’ve developed solutions that eliminate manual labor, reduce cycle times, and deliver consistent, high-quality results.

More Tumbling Media Manufacturers

What is Tumbling Media?

Tumbling media are specially engineered materials, typically composed of abrasives and binders, designed for use in mass finishing processes such as vibratory finishing and barrel tumbling. The main purpose of tumbling media is to deburr, clean, polish, burnish, and refine the surface of various components—especially small parts made from metal, plastic, or other materials. By using a tumbling technique, these media interact with workpieces to smooth rough surfaces, round sharp edges, and enhance the aesthetic and functional properties of parts.

Tumbling media are essential in numerous industrial applications, including metal finishing, automotive component manufacturing, aerospace part production, medical device fabrication, and jewelry making. Their use ensures consistent, high-quality surface finishing, often reducing the need for manual labor and increasing efficiency for high-volume production.

How does the tumbling process work? In a typical finishing process, parts are placed in a tumbling machine along with a carefully selected media and a compound. The equipment then vibrates or rotates, causing the media and parts to interact. This action abrades, polishes, or cleans the workpieces, depending on the desired outcome and media selection.

Types of Tumbling Media

Choosing the right tumbling media is critical for achieving your desired surface finish, minimizing part damage, and optimizing process efficiency. Tumbling media are available in a variety of materials, shapes, and sizes, each designed for specific finishing tasks and compatible with different substrates and finishing machines. The main types of tumbling media include:

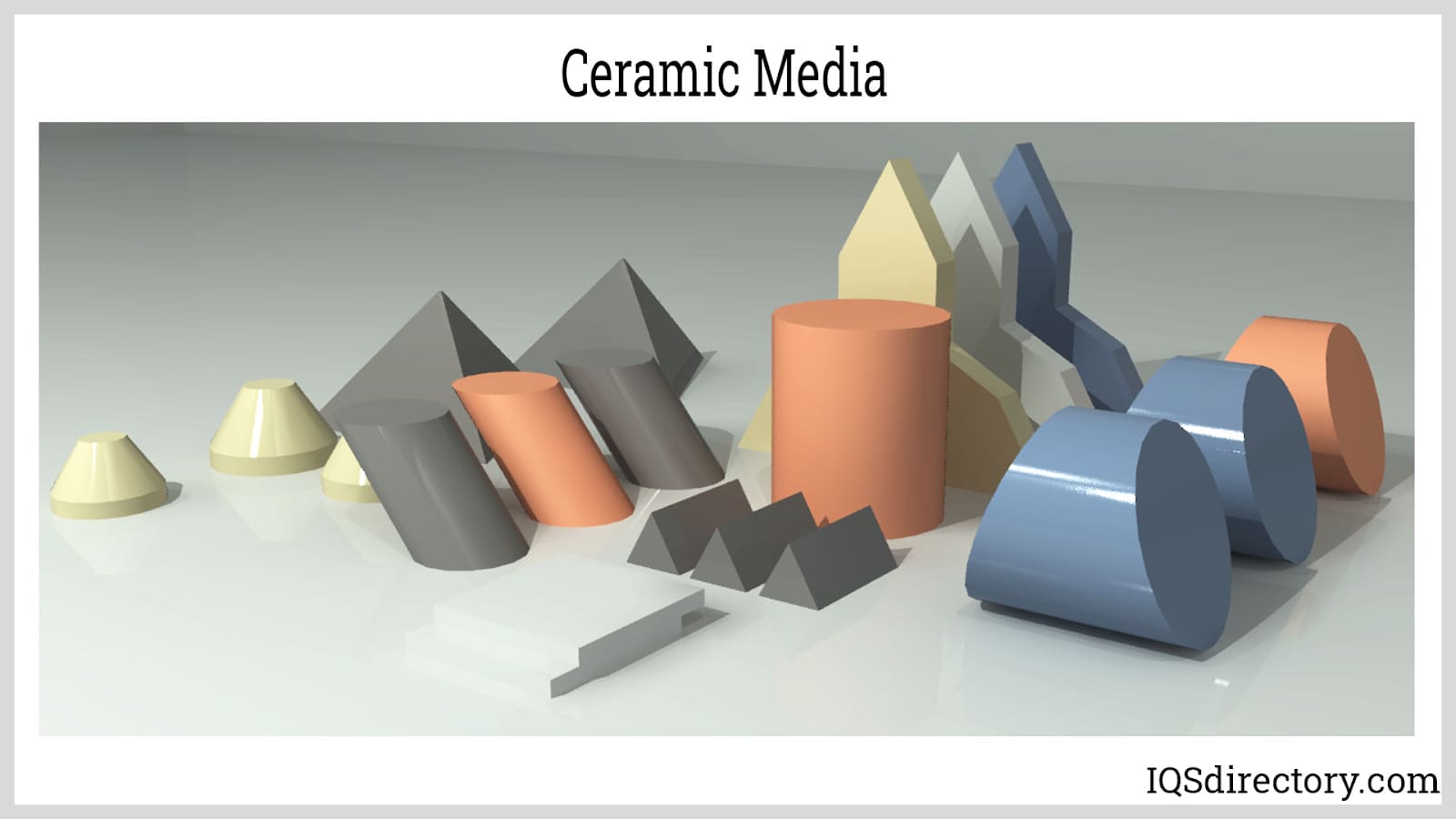

Ceramic Media

Ceramic tumbling media is the most common finishing media in industrial mass finishing applications. Manufactured from a blend of abrasive grains and clay, ceramic media is fired at high temperatures to achieve exceptional hardness, density, and durability. Because of these properties, ceramic media is ideal for aggressive deburring, edge radiusing, rust removal, and polishing hard metals such as steel, stainless steel, titanium, and iron.

Key benefits of ceramic tumbling media:

- Efficient removal of burrs and sharp edges on hard metals

- High cutting power for rapid material removal

- Long service life, even under heavy-duty conditions

- Available in a variety of shapes (triangles, cylinders, cones, etc.) and abrasive grades for different finishing needs

Common applications: Deburring stamped or machined components, surface preparation before coating or plating, cleaning rust or scale from metal parts, and achieving a uniform, smooth finish.

Considerations: Due to their density and abrasive nature, ceramic media can sometimes chip, and small ceramic particles may become lodged in recessed areas or holes of intricate parts. It's important to select the proper media size and shape for your application to minimize this risk.

Steel Media

Steel tumbling media is manufactured from hardened carbon steel or high-density stainless steel alloys. Steel media is recognized for its exceptional strength, mass, and impact resistance, making it the preferred choice for heavy-duty burnishing, polishing, and ball burnishing applications. These features also translate to an extended service life and reduced replacement costs.

Advantages of steel tumbling media:

- Produces a bright, mirror-like finish on metals

- Excellent for burnishing brass, copper, aluminum, and precious metals

- Non-abrasive – removes burrs and polishes without substantial material loss

- Highly durable and reusable, resulting in lower operational costs

Use cases: Steel media is used extensively in the finishing of firearm cartridge cases, jewelry, automotive components, and plastic parts requiring a smooth, lustrous finish. It is also ideal for burnishing parts prior to electroplating or anodizing.

Decision factors: When using steel media, consider the need for rust inhibitors or regular maintenance to prevent oxidation, especially when working with carbon steel media. For stainless steel media, corrosion resistance is significantly higher, making it suitable for wet tumbling and aqueous processes.

Plastic Media

Plastic tumbling media is essential for the gentle polishing, deburring, burnishing, and cleaning of softer metals and delicate parts. Commonly used on brass, zinc, aluminum, and plastic components, plastic media offers lower density compared to ceramic or steel media, which allows it to perform vibratory finishing without damaging fragile, thin-walled, or threaded parts.

Why choose plastic tumbling media?

- Minimizes impingement and distortion on soft or thin parts

- Produces soft, bright, and smooth surfaces on workpieces

- Ideal for finishing die-cast parts, electronic housings, and jewelry components

- Available in a variety of formulations for different cutting and polishing needs

Plastic media is typically made from polyester, urea, or formaldehyde-based polymers. The composition and abrasive content can be adjusted to achieve specific finishing results. For example, low-density plastic media is ideal for gentle deburring, while high-density and high-performance formulations are suitable for faster material removal or harder substrates.

Low Density Plastic Media

Low-density plastic media is recommended for finishing softer materials, such as zinc and aluminum, and for processes that require minimal surface distortion. Common applications include flash removal, gentle deburring, burnishing, and surface preparation prior to painting or coating.

High Density Plastic Media

High-density plastic media is formulated for more aggressive deburring and finishing of ferrous and non-ferrous metals. It is suitable for intricate components, fine-featured parts, and applications that demand faster cutting rates.

High Performance Density Plastic Media

Designed for the toughest finishing challenges, high-performance density plastic media is primarily used for deburring and polishing ferrous metals and hard-to-finish components. It delivers rapid cycle times and consistent surface quality.

Organic Media

Organic tumbling media includes lightweight, biodegradable materials such as walnut shells, crushed corn cobs, and wood pegs. Due to their natural composition, organic media is environmentally friendly, non-toxic, and safe for use with delicate or precision components.

Benefits of organic tumbling media:

- Perfect for light to medium deburring, cleaning, and polishing tasks

- Excellent for use with jewelry, electronics, and soft metals

- Highly absorbent—removes oils, moisture, and contaminants from workpiece surfaces

- Leaves a glossy, residue-free finish when used with polishing compounds

Use cases: Organic media are widely used in the jewelry industry for mass finishing of gold, silver, and gemstone pieces. They are also employed for drying parts after wet vibratory finishing and removing calcium or mineral deposits from water-exposed components.

Looking for an eco-friendly finishing solution? Consider organic tumbling media for applications where sustainability, safety, and gentle cleaning are top priorities.

Applications of Tumbling Media

What are the most common uses for tumbling media? Tumbling media play a critical role in many manufacturing and finishing processes, supporting industries like automotive, aerospace, firearms, jewelry, medical devices, and electronics. Some of the most common applications include:

- Polishing firearm cartridge cases: Cleaning and polishing brass casings in a vibratory bowl finisher helps reloaders save on ammunition costs while ensuring reliable firearm performance. Steel and ceramic media are popular choices for this task.

- Jewelry finishing: Mass finishing systems for jewelry leverage tumbling media to efficiently deburr, burnish, and polish rings, bracelets, and intricate pieces, providing a high-gloss, professional finish while reducing manual labor.

- Deburring automotive and aerospace components: Tumbling media are essential for removing burrs, sharp edges, and surface imperfections from machined, stamped, or cast parts. This improves part safety, fit, and operational performance.

- Cleaning and descaling parts: Removing rust, scale, and mineral deposits from metal parts is a key use of abrasive tumbling media, particularly in maintenance and restoration applications.

- Surface preparation: Tumbling media prepare components for subsequent processes like coating, painting, anodizing, or electroplating by creating a uniform, clean, and adhesion-friendly surface.

- Drying and oil removal: Organic media such as corn cob granules are used to absorb moisture and oils from finished parts, reducing corrosion risk and ensuring parts are clean and ready for final assembly or packaging.

Wondering which tumbling media is best for your application? The ideal media choice depends on your workpiece material, desired finish, production volume, and finishing equipment. Consulting with a knowledgeable tumbling media supplier can help you identify the optimal media for your process.

Benefits of Using Tumbling Media

Why invest in quality tumbling media for your finishing operations? The choice of tumbling media can significantly impact both the efficiency and quality of your finishing process. Here are key benefits:

- Time and labor savings: Mass finishing with tumbling media automates surface treatment, reducing manual labor and increasing throughput for high-volume production lines.

- Consistent, high-quality finishes: Properly selected media ensures repeatable, uniform results, whether you're deburring, polishing, or cleaning parts.

- Reduced rejects and rework: Efficient deburring and edge radiusing minimize part defects, lower scrap rates, and improve downstream yield.

- Cost efficiency: Durable media with long service life reduces replacement frequency and media consumption, optimizing operational costs.

- Versatile process control: A wide range of available media types, shapes, and abrasive grades allows you to tailor the process to your specific finishing requirements.

- Enhanced safety and ergonomics: Automated tumbling processes remove the need for hazardous manual finishing tasks, protecting workers and improving workplace safety.

Curious about how different tumbling media types affect your finishing results? Explore our resources or contact our team for guidance on selecting the best tumbling media for your industry and application.

How to Choose the Right Tumbling Media

What factors should you consider when selecting tumbling media? Choosing the right tumbling media is essential for achieving optimal results and avoiding potential issues such as part damage or contaminated finishes. Key decision factors include:

- Material of the workpiece: Hard metals (steel, titanium) benefit from ceramic or steel media, while soft metals (aluminum, brass) and plastics typically require plastic or organic media.

- Desired finish: Choose media with the appropriate abrasive grade for your finishing goal—coarse for aggressive cut-down, fine for polishing.

- Part geometry: Small or intricate parts may require fine media shapes to access recesses and avoid lodging.

- Finishing equipment: Ensure compatibility between your tumbling machine (vibratory, rotary barrel, centrifugal disc, etc.) and the selected media.

- Cycle time and production volume: High-density or high-performance media may reduce cycle times for large batches, improving productivity.

- Environmental and regulatory considerations: Organic or plastic media may be preferred for applications with strict environmental requirements.

Want to compare media performance for a specific task? Request product samples or run test batches with different media types to evaluate surface finish, cycle time, and process yield before making a final selection.

Choosing the Correct Tumbling Media Supplier

How do you find a reliable tumbling media supplier? Partnering with an experienced and reputable tumbling media manufacturer is vital to ensure consistent product quality, technical support, and on-time delivery. Here are tips for selecting the right supplier:

- Compare at least 6 manufacturers using our curated list of tumbling media companies.

- Review each supplier’s business profile to assess their expertise, product range, and industry certifications.

- Use our website previewer to explore each company’s finishing solutions, media formulations, and application capabilities.

- Leverage our RFQ form to contact multiple media suppliers simultaneously and request competitive quotes.

- Evaluate customer testimonials, case studies, and technical support resources to gauge supplier reliability and responsiveness.

Need help sourcing the best tumbling media for your process? Our team can connect you with leading manufacturers, provide technical guidance, and facilitate product trials—ensuring you choose the right media for your specific finishing requirements.

Frequently Asked Questions About Tumbling Media

What is the shelf life of tumbling media?

Tumbling media generally has a long shelf life when stored in a dry, cool environment. Ceramic and steel media can last for years without degradation, while organic and plastic media should be kept away from moisture to prevent breakdown. Always follow the manufacturer’s storage guidelines.

How do I know when to replace my tumbling media?

Media should be replaced when it loses its shape, becomes excessively small, or no longer delivers the required surface finish. Monitoring process results and performing regular inspections ensures optimal finishing quality.

Can tumbling media be recycled or reused?

Many types of tumbling media—especially steel and ceramic—are reusable for multiple cycles. Organic and plastic media can also be reused until they degrade or lose effectiveness. Check with your supplier regarding recycling options or environmentally friendly disposal methods.

How do I prevent media lodging in small holes or recesses?

Select media shapes and sizes that avoid getting trapped in part features. For intricate or threaded parts, consider using finer media or specialized shapes designed for easy removal.

What compound should I use with my tumbling media?

The choice of compound depends on your application—cleaning, polishing, degreasing, or rust removal. Water-based, alkaline, or acidic compounds are available for different needs. Consult with your media supplier for recommendations tailored to your process.

Start Your Tumbling Media Selection Today

Ready to enhance your finishing process with the right tumbling media? Explore our extensive directory of tumbling media manufacturers, review in-depth company profiles, and request personalized quotes to streamline your purchasing process. Whether you need ceramic, steel, plastic, or organic finishing media, our resource hub connects you to the best suppliers in the industry.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services